- What's New?

- Featured Section

- Tech Section

- Image Gallery

- Video Gallery

- 2011 Daisy National BB Gun Championship Match

- Airgun Expo Show Circa 2003 - Little Rock, AR

- Benjamin Marauder Air Pistol: Increasing Velocity By Varying Transfer Port Sizes

- Diana Model 27 Pre-War (WWII) Circa 1923 - .177 Cal.

- Folding Stock Adapted To A Crosman 1377 Air Pistol

- Unboxing The Benjamin Marauder Air Pistol

- Mega-Dart Blowgun Rifle MX-7 : Ultimate Zombie Defense

- Prototype Trigger Assembly For a Dual Tubed Crosman 1377 Pistol

- Tuning The Benjamin Marauder Air Pistol

- Links

- Classifieds

Restoring a Mega-Dart MX-5 Blowgun Dart Pistol

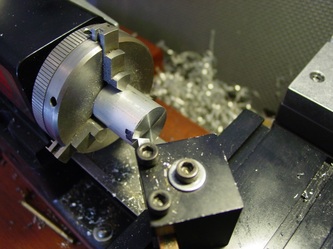

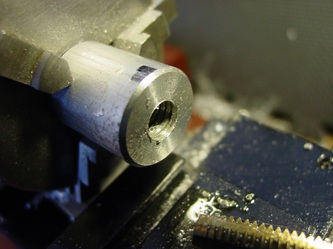

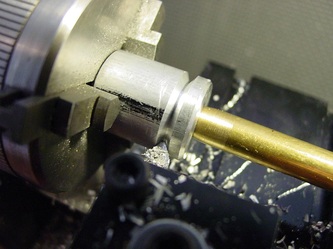

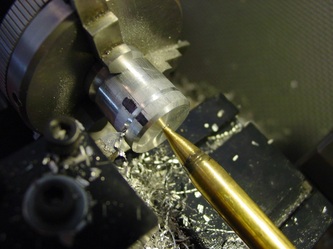

Many times items are acquired that need restoration in order to work properly. Such is the case with a Mega-Dart MX-5 blowgun that I purchased. A few minor parts such as the trigger guard, a few screws, and the original camo wrapping were missing but more importantly the MX-5 wasn't building any air pressure. The original piston seal though cosmetically perfect no longer sealed the compression tube with enough force to propel a dart out of the barrel. So a new piston was made incorporating common Buna o-rings as the sealing media. The series of photos below document the restoration process.

The primary tools used to make the piston were a Sherline lathe and a Taig milling machine. The interior of the compression tube was smoothed with a swab of Scotchbrite pad attached to a wooden dowel rotated by an electric drill inside the tube. The residual adhesive left behind from the original camo tape was removed with 91% Isopropyl Alcohol with no ill effects to the plastic components.

The primary tools used to make the piston were a Sherline lathe and a Taig milling machine. The interior of the compression tube was smoothed with a swab of Scotchbrite pad attached to a wooden dowel rotated by an electric drill inside the tube. The residual adhesive left behind from the original camo tape was removed with 91% Isopropyl Alcohol with no ill effects to the plastic components.